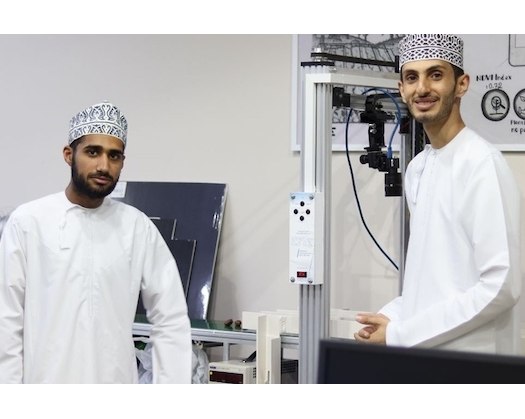

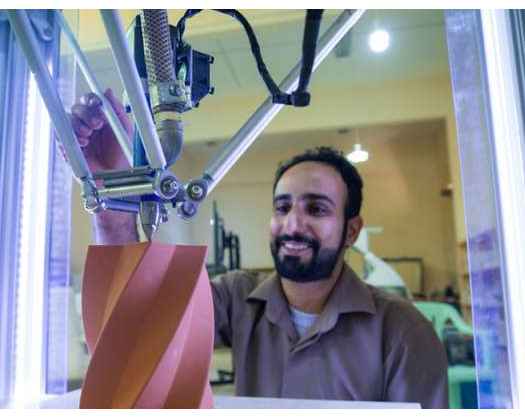

A team of students from Sultan Qaboos University's College of Engineering has successfully developed a technical innovation that combines computer vision and robotic systems to assess the quality of dates. By integrating artificial intelligence technology into the food industry, their project aims to enhance food quality, automate inspection and sorting processes, increase production capacity, and contribute to food security.

Asaad bin Saeed Al Hinai, a member of the student project team, emphasized the significance of the date industry in Oman, as it serves as a vital source of income and trade. However, date producers often face challenges in the sorting process, particularly in identifying dates that are spoiled or unsuitable for consumption. The implementation of artificial intelligence technology is crucial in improving the sorting process in date factories. Through the utilization of computer vision algorithms and robotics, the team successfully developed a date sorting system.

Al Hinai further explained that the system employs artificial intelligence to automatically sort dates. It streamlines the process of distinguishing edible dates from spoiled ones, automatically assesses the quality of dates, identifies their condition as they pass through the production line, and directs them to the appropriate path. Additionally, the system keeps track of the number of sorted dates and calculates the percentage of spoiled dates in comparison to good ones.

Ahmed bin Mohammed Al Habsi, a member of the student project team, emphasized the significance of integrating artificial intelligence into food sorting processes. The process commences with the dates being transported into the production line via a conveyor belt. Subsequently, the dates are captured from above using a high-resolution camera. Computer vision is then utilized to distinguish between good and spoiled dates. The dates are finally sorted through specialized gates along the production line.

Saleh bin Yahya Al Ghanami, another member of the student project team, highlighted the challenges faced by factories in manually sorting out spoiled or unusable products. This manual method is not only economically costly but also risks compromising the quality of dates due to human error.

Al Ghanami emphasized that the system's efficiency is gauged by the sorting speed (number of dates sorted per hour) and the error rate in examination and sorting. He underscored that the system enhances the efficiency of date sorting compared to conventional methods.

It is important to note that the artificial intelligence system can be implemented in various other sectors, including inspection and quality control processes in different factories requiring precise product quality assessment.